Our Vision

A world where housing and infrastructure are affordable and sustainable

News

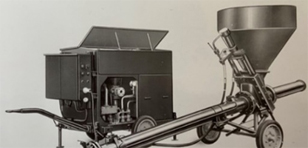

of the first hydraulic concrete pump handover

World first: Putzmeister and STRABAG subsidiary ZÜBLIN produce complete and supporting concrete walls from the 3D concrete printer for the first time

Have you already read the latest issue of Putzmeister Post?

Success Stories

Putzmeister Wetkret 5 is the new Putzmeister equipment that Lurpelan Tunneling has acquired for the support works of the tunnels through which the railway tracks that will serve as a link with our Portuguese neighbours will run.

Modular construction 4.0. At the precast plant of Deutsche Modulhausfabrik GmbH (DMF), employees are reconceptualising construction with the production of Lechner cubes.

This application describes the succcessful customization and integration of an RV16 hydraulic rotary distributor with an EQV squeeze valve at a waste management facility in Toronto, Canada.

Products

Insight into the production of concrete pumps

at Putzmeister America in Racine, Wisconsin

Production of mortar machines and screed conveyors at Putzmeister Mörtelmaschinen in Germany